Razor Barbed Wire Machinery-Concertina Razor wire production line -BTO 22 Barbed tape Making Machine

As an ISO Certified manufacturer, we supply prime quality Razor Barb Wire Making Machine for production of razor blade barbed wire and setting up concertina razor barbed wire plants and factories.

Razor barbed wire, also known as razor blade barbed wire, prison fence barbed wire, razor belt, razor tape and hexagonal barbed wire, is a new type of protective fencing. The razor barbed wire utility model has the characteristics of economy, practicality, good anti-blocking effect and convenient construction. At present, Razor barbed wire has been widely used in industrial and mining enterprises, garden apartments, border posts, military fields, prisons, detention centers and governments buildings and safety facilities in many countries.

Razor Wire Machines - Press and Parts for Major Processing Steps

Razor Barbed Wire Machine, simplified as razor wire machine, is special equipment for producing razor barbed wire. The machine consists mainly of feeding machinery, stamping machine tool, product material recycling machine, coiling machine and wire assembling machine.

With rich experiences in razor barbed wire manufacture, our professional technicians understand how to constantly improve the design of machine and tools for high efficiency production and reliable quality control. Our machine is designed to produce razor blade type barbed wire of various types with reliable production performance.

Razor wire machines/ tools for major processing steps:

Strip Punching: 130mm wide steel strip can punch 9 blades, 154mm wide steel plate can punch 9 blades, 176mm wide steel strip / plate can punch 13 blades. The wider the steel sheet, the less waste and the more material you save in razor blade processing.

A 25-ton punching machine is required to punch 9 single blades, which is a low output. A 63-ton punch press is required to punch 9 double and 11 blades. 63-ton punch press is currently used in the market. A 80-ton punch is required to punch 13 blades. This type of blade barbed wire machine is newly researched and put on the market, with high output and less waste.

Features:

Razor barbed wire machine is light, easy to operate, high efficient.

Using our razor barbed wire machine can save you twenty percent of raw materials in production.

Concertina Razor Barbed Wire Manufacturing Machines with Spare Parts and Related Accessories

This type of blade type razor barbed wire machine is recommended for setting up full range razor wire (BTO 10 to CBT 65) manufacturing plant.

The production line including:

De-Coiler

Strip Punching Press Machine for Razor Blades Production

Razor Strips Recoiling Machine

Razor Strips De – coiler

Wire Pay Off

Razor Blade and Wire Assembling (Forming Machine) Machine

Re Coiler

Strip Punching Press Machine / Razor Blades Machine

Technical detail:

Blade width 13±1 ~ 32±2mm

Blade Thickness: 0.5±0.05 ~ 0.6±0.05mm

Blade length: 10±1 ~ 65±2

Blade pitch: 26±1 ~ 100±2mm

Blade material: Stainless steel

Number of die for various shape of blade: Min. 07 blade types

Concertina Wire Manufacturing Line includes:

Clip Cutting Press Machine with related accessories and Concertina Wire Crimping Pneumatic Gun with related accessories.

Supplied with Concertina wire machine mould.

With the machine lines, we also supply following after-sales service and technical services:

Concertina / Razor blade manufacturing flow chart;

Original catalogue in English;

Special tools / fixture required to be provided for manufacturing the concertina razor wire;

Machine installation, trial run and operational with maintenance training at premises. The duration of training normally goes at least 02 weeks at buyers cost;

Confirmation certificate for supply of spare parts for 10 years from manufacturer;

Machine manufacturer ISO Certificate;

Guranteed successful completion of installation, operation and trial run of the machine;

All related work for installation will be done by supplier including internal wiring main distribution board and distribution with circuit breaker;

Standard oiling, greasing, cooling and chips removal system should be built in with the machine;

List of spare parts required for 05 years operation supplied with offer.

Technical Specifications of Concertina Wire / Razor Barbed Wire Manufacturing Machines with Related Accessories

| 1 x De- Coiler | ||

Particulars |

User’s Requirement |

Manufacturer’s Specification |

Country of Origin |

China |

China |

Country of Assembly |

China / Any Country |

China |

Model |

To be mentioned |

Standard/customized |

Inner diameter |

To be mentioned |

Standard/customized |

Outer diameter |

To be mentioned |

Standard/customized |

Loading weight |

To be mentioned |

Standard/customized |

Motor power |

To be mentioned |

Standard/customized |

Rotation speed |

To be mentioned |

Standard/customized |

Size of machine |

To be mentioned |

Standard/customized |

Weight of machine |

To be mentioned |

Standard/customized |

Warranty repair or replacement |

Min. 01 Year. |

Min. 01 Year. |

| 1 x Strip Punching Press Machine / Razor Blades Machine (Blade Profile BTO-10 to CBT-65) | ||

Particulars |

User’s Requirement |

Manufacturer’s Specification |

Country of Origin |

Any Country |

China |

Country of Assembly |

Any Country |

China |

Model |

To be mentioned |

Standard/customized |

Blade width |

13±1 ~ 32±2mm |

13±1 ~ 32±2mm |

Blade Thickness |

0.5±0.05 ~ 0.6±0.05mm |

0.5±0.05 ~ 0.6±0.05mm |

Blade length |

10±1 ~ 65±2 |

10±1 ~ 65±2 |

Blade pitch |

26±1 ~ 100±2mm |

26±1 ~ 100±2mm |

Blade material |

Stainless steel |

Stainless steel |

Number of die for various shape of blade |

Min. 07 types |

Min. 07 types |

Stroke per minute |

To be mentioned |

Standard/customized |

Production rate (meter per minute) |

To be mentioned |

Standard/customized |

Number of strip |

7 / 9 no. |

7 / 9 no. |

Power supply (single / three phase) |

To be mentioned |

Standard/customized |

Motor power |

To be mentioned |

Standard/customized |

Machine dimension |

To be mentioned |

Standard/customized |

Machine weight |

To be mentioned |

Standard/customized |

Standard tools and accessories |

To be mentioned |

Standard/customized |

Optional tools and accessories |

To be mentioned |

Standard/customized |

Warranty repair or replacement |

Min. 01 Year. |

Min. 01 Year. |

Confirmation for supply of spare parts, after sales service, operation, maintenance, control system and software etc. |

Min. 10 Years |

Min. 10 Years |

Optional dies & punches. |

To be mentioned |

|

| 1 x Razor Strips Recoiling Machine: | ||

Particulars |

User’s Requirement |

Manufacturer’s Specification |

Country of Origin |

Any Country |

China |

Country of Assembly |

Any Country |

China |

Model |

To be mentioned |

Standard/customized |

Inner diameter |

To be mentioned |

Standard/customized |

Outer diameter |

To be mentioned |

Standard/customized |

Loading weight |

To be mentioned |

Standard/customized |

Motor power |

To be mentioned |

Standard/customized |

Rotation speed |

To be mentioned |

Standard/customized |

Size of machine |

To be mentioned |

Standard/customized |

Weight of machine |

To be mentioned |

Standard/customized |

Warranty repair or replacement |

Min. 01 Year. |

Min. 01 Year. |

| 1 x Razor Strips De – coiler | ||

Particulars |

User’s Requirement |

Manufacturer’s Specification |

Country of Origin |

Any Country |

China |

Country of Assembly |

Any Country |

China |

Model |

To be mentioned |

Standard/customized |

Inner diameter |

To be mentioned |

Standard/customized |

Outer diameter |

To be mentioned |

Standard/customized |

Loading weight |

To be mentioned |

Standard/customized |

Motor power |

To be mentioned |

Standard/customized |

Rotation speed |

To be mentioned |

Standard/customized |

Size of machine |

To be mentioned |

Standard/customized |

Weight of machine |

To be mentioned |

Standard/customized |

Warranty repair or replacement |

Min. 01 Year. |

Min. 01 Year. |

| 1 x Wire Pay Off : | ||

Particulars |

User’s Requirement |

Manufacturer’s Specification |

Country of Origin |

Any Country |

China |

Country of Assembly |

Any Country |

China |

Model |

To be mentioned |

Standard/customized |

Inner diameter |

To be mentioned |

Standard/customized |

Outer diameter |

To be mentioned |

Standard/customized |

Loading weight |

To be mentioned |

Standard/customized |

| 1 x Razor Blade and Wire Assembling (Forming Machine) Machine : | ||

Particulars |

User’s Requirement |

Manufacturer’s Specification |

Country of Origin |

Any Country |

China |

Country of Assembly |

Any Country |

China |

Model |

To be mentioned |

Standard/customized |

Wire diameter (single strand) |

2.5±0.1mm and max. dia to be mentioned |

Standard/customized |

Wire material |

Spring Steel (Galvanized) |

Spring Steel (Galvanized) |

Production rate (meter per minute) |

To be mentioned |

Standard/customized |

Power supply (single / three phase) |

To be mentioned |

Standard/customized |

Motor power |

To be mentioned |

Standard/customized |

Machine dimension |

To be mentioned |

Standard/customized |

Machine weight |

To be mentioned |

Standard/customized |

Standard tools and accessories |

To be mentioned |

Standard/customized |

Optional tools and accessories |

To be mentioned |

Standard/customized |

Optional dies for assembling |

|

Available |

Warranty repair or replacement |

Min. 01 Year. |

Min. 01 Year. |

Confirmation for supply of spare parts, after sales service, operation, maintenance, control system and software etc. |

Min. 10 Years |

Min. 10 Years |

| 1 x Re Coiler | ||

Particulars |

User’s Requirement |

Manufacturer’s Specification |

Country of Origin |

Any Country |

China |

Country of Assembly |

Any Country |

China |

Model |

To be mentioned |

Standard/customized |

Inner diameter |

To be mentioned |

Standard/customized |

Outer diameter |

To be mentioned |

Standard/customized |

Loading weight |

To be mentioned |

Standard/customized |

Standard length per coil |

To be mentioned |

Standard/customized |

Warranty repair or replacement |

Min. 01 Year. |

Min. 01 Year. |

| Specification | Thickness | Wire Diameter | Blade Length | Blade Width | Blade Pitch |

| BTO-10 | 0.5±0.05 | 2.5±0.1 | 10±1 | 13±1 | 26±1 |

| BTO-18 | 0.5±0.05 | 2.5±0.1 | 18±1 | 15±1 | 33±1 |

| BTO-22 | 0.5±0.05 | 2.5±0.1 | 22±1 | 15±1 | 34±1 |

| BTO-28 | 0.5±0.05 | 2.5 | 28 | 15 | 45±1 |

| BTO-30 | 0.5±0.05 | 2.5 | 30 | 18 | 45±1 |

| CBT-60 | 0.6±0.05 | 2.5±0.1 | 60±2 | 32±1 | 100±2 |

| CBT-65 | 0.6±0.05 | 2.5±0.1 | 65±2 | 21±1 | 100±2 |

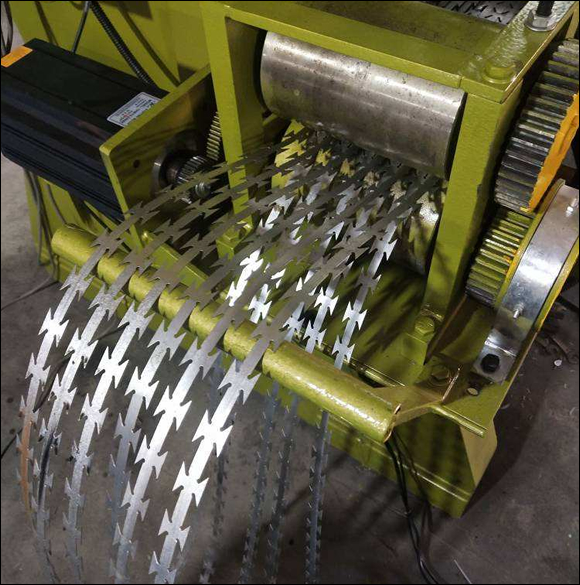

Machinery photoes:

Razor wire machine composed of the main punching machine of strip plates to blades, with razor wire coiling machine.

Punching of flat razor wire, out of steel or stainless steel

strips

Concertina Razor Wire Machine to produce double loop concertina:

Concertina barbed wire machine (tape type BTO-22)

We supply standard and customized machines to meet customers specific production requirement.

Customized Machines

Razor Blade Barbed Wire Making Machine

Razor Blade Barbed Wire Machine – 9 Strips.

Sets with Extra Dies.

Razor Wire Making System

40 ton press with capacity of making 9 strip BTO and 5 strip CBT.

Razor welded wire fence machine

Razor Barb Wire Machine General Dimensions, Weight, Power, Voltage

Overal Diamension |

L*W*H:1100MMX1000MMX1700MM |

Rated Voltage |

380V |

Power |

1.5KW |

Producing speed |

220-280m/h |

Weight |

800KG |

Overal Diamension |

L*W*H:1100mmx750mmx1200mm |

Rated Voltage |

380V |

Power |

1.5kw |

Producing speed |

80kg/h |

Weight |

300kg |

Overal Diamension |

L*W*H: 1200MMX1000MMX1900MM |

Rated Voltage |

380V |

Power |

2.2KW |

Producing speed |

220-280m/h |

Weight |

1500KG |

Overal Diamension |

L*W*H:1100mmx750mmx1200mm |

Rated Voltage |

380V |

Power |

1.5kw |

Producing speed |

80kg/h |

Weight |

300kg |

Contact us for customized machine products and services:

Send us your detail requirement for razor wire production line such as razor wire types, production capacity, stainless steel or galvanized razor barbed tape material, we will provide us a complete offer of the razor wire machines with the following materials:

a,Machine price with standard accessories;

b,List of parts and the standard accessories;

c,Optional accessories with price of each items;

d,Fast moving Spare parts list with price for each item;

e,Cost of installation, trial run and training;

f,

Printed catalogue / e-catalog.