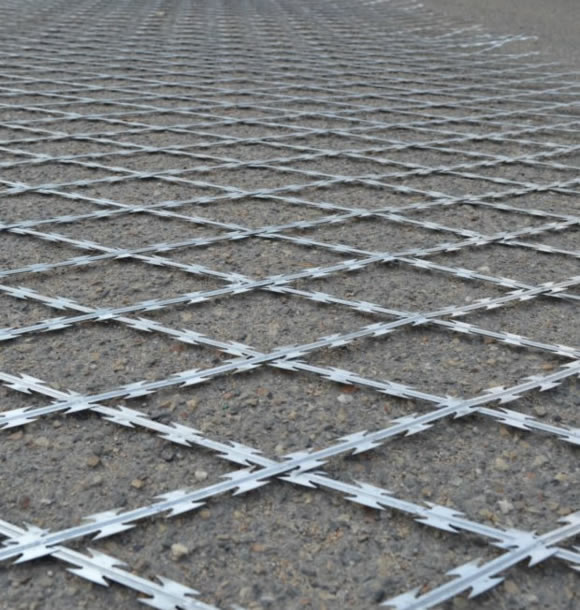

Razor blade protection mesh fencing system-Razor Blade Tape, razor mesh,TApe and welded fence

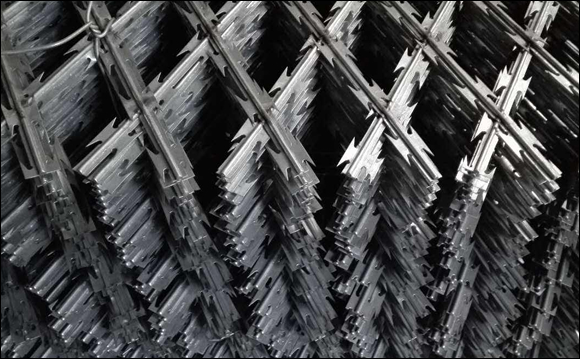

Material: Galvanized blade, stainless steel blade.

Features: Compact and uniform structure, high safety property, suitable for the protection of prison and military sites.

Specifications: Razor blade wire mesh sheet can be made according to dimension requirement of customer; the special product is manufactured according to the drawing.

Uses: Flat razor blade barbed tape and mesh are commonly used with welded wire mesh fences.

Customized razor blade mesh with the specifications listed below:

Sheet thickness: 0.5mm

Wire diameter: 2.50mm

Blade length: 300mm

Blade width: 180mm

Blade spacing: 451mm

Finish: Galvanized steel blade mesh

Tensile strength of the wire: 1500 N/ square millimeter

Welded razor wire mesh diamond shape, BTO-22 and BTO-30 with hole aperture 75 mm × 150 mm.

Razor Mesh and Tape

Razor blade mesh ( 30 x 15 cm, height 210 cm)

Razor blade tape ( 1,5 cm x 200 m)

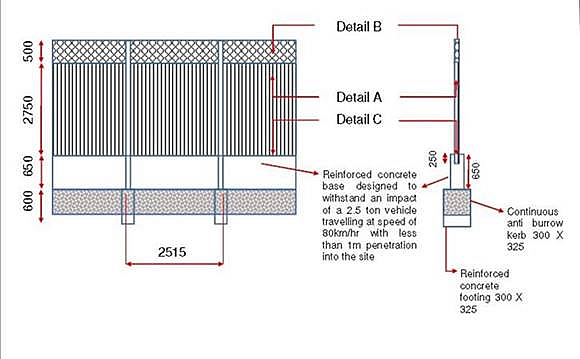

Welded Razor Wire Mesh Security Fence Grids

Welded Mesh Fence + Stainless Steel Razor Blade Tape ( SS316 Blade and SS Core Wire)

Welded mesh fence with razor blade topping

MESH SPACING : 12.5MM (H) X 75MM (L)

FENCING HEIGHT : 3000MM

REMARK : FLAT PANEL

RAZOR HEIGHT @ 500MM

Steel posts and struts shall comply with the following standards:

(i) BS 4848: Part 4 and BS 4360 (grade 40c) for rolled steel angle (RSA)

(ii) BS 4848: Part 2 and BS 4360 (grade 43c) for rectangular hollow section (RHS)

PROTECTION

(a) All steel components shall be protected against corrosion using hot dip galvanizing complying with BS EN ISO 1461. All rust, loose scale, oil and dirt shall be removed from all surfaces before treatment.

(b) Small areas of hot dip galvanized coating damaged by welding, cutting or by excessively rough treatment during transit and erection shall be renovated either by the use of low melting point zinc alloy repair rods or powders made specifically for this purpose, or by the use of at least two coats of good quality zinc-rich paint complying to BS 4652.

Sufficient material shall be applied to provide a zinc coating at least equal in thickness tothe original layer

Razor blade topping

(a)Topping Supports Mounting Bracket

50mm x 75mm x 6mm x 75mm long mild steel angle to BS4848 with 12mm diameter holes for fixing to posts and for topping mounting. Protective finish to be hot dip galvanised to BS729.

(b) Topping Flexible Rubber Sleeves

50mm outer diameter, 12mm inside diameter x 30mm long rubber sleeves to BS4255.

(c) Topping Support Arms

50mm x 50mm x 5mm x 600mm long mild steel angle to BS4848 with 12mm diameter holes for flexible rubber bushed and 6mm vertical slots for barbed razor tape. Protective finish to be Hot Dip Galvanised to BS729.

(d) Security Topping

Install 18mm wide flat stainless steel 316 razor tape with both edges cut to a double barbed profile at 25mm centres and:

(i) Crimped to a 2.5mm diameter stainless steel spring core wire with a wraparound of 220-240 degrees

(ii) The razor tape shall be manufactured as per ASTM F1379-95 standards and have a minimum tensile strength of 1350 MPA

(e) Topping

(i) Bolt to posts.

(ii) Bolt to mounting brackets through flexible mounting ensuring flexible mountings are compressed but not distorted.

(iii) Extend barb tape coil so that coils are placed at centres of arms.

(iv) Secure to arms at each point of contact with hog rings/tying wire and clip adjacent ends to coils with fixing clips.