Barbed Tape High Security Fence and Gates with Cable Reinforcement for Military and Critial Facility Entry Control Projects

We supply high security fencing solution for area control by combing four major components:

Barbed Tape, Fences, High Security Sliding Gate, Wire Ropes.

Supply and installing high-security fence around the perimeter of the facility, shall ensure the products compliance with relevant security standards and regulations, also the fencing system is integrated with advanced surveillance and detection system.

Surveillance systems with the fencing system:

Install surveillance cameras, motion sensors, and other detection devices along the perimeter fence to enhance situational awareness.

High Security Fencing System Solution for Assets and Facilities

The fencing system is designed for the safety and security of personnel, assets and facilities in a high-risk environment.

Primary components of the fencing system include three means of protection:

Chain Link Fence: Galvanized chain link fence forms the first layer of the perimeter security system. This type of mesh fence provides a visible deterrent and serves as a physical barrier against unauthorized entry.

Barbed Tape: Positioned atop the chain link fence is a layer of barbed tape, also known as razor wire. Barbed tape consists of sharp, jagged edges that act as a formidable deterrent to potential intruders, further enhancing the security of the perimeter.

Cable Reinforcement: In addition to the chain link fence and barbed tape, the perimeter security system include cable reinforcement. Steel cables are installed along the length of the fence and gates, providing additional support.

Project example - High Security Fence and Gates for entry control project

High Security Fence and Security Gates, Mesh Fabric Powder Coated RAL 8002 (signal brown)

HIGH-SECURITY FENCES (CHAIN LINK AND ORNAMENTAL) AND GATES

PART 1 GENERAL

1.1 REFERENCES

The publications listed below form a part of this specification to the extent referenced. The publications are referred to within the text by the basic designation only.

| ASTM INTERNATIONAL (ASTM) | |

| ASTM A116 | (2011) Standard Specification for Metallic-Coated, Steel Woven Wire Fence Fabric |

| ASTM A121 | (2013) Standard Specification for Metallic-Coated Carbon Steel Barbed Wire |

| ASTM A153/A153M | (2016) Standard Specification for Zinc Coating (Hot-Dip) on Iron and Steel Hardware |

| ASTM A240/A240M | (2019) Standard Specification for Chromium and Chromium-Nickel Stainless Steel Plate, Sheet, and Strip for Pressure Vessels and for General Applications |

| ASTM A307 | (2014; E 2017) Standard Specification for Carbon Steel Bolts, Studs, and Threaded Rod 60 000 PSI Tensile Strength |

| ASTM A392 | (2011a; R 2017) Standard Specification for Zinc-Coated Steel Chain-Link Fence Fabric |

| ASTM A478 | (1997; R 2019) Standard Specification for Chromium-Nickel Stainless Steel Weaving and Knitting Wire |

| ASTM A491 | (2011; R 2017) Standard Specification for Aluminum-Coated Steel Chain-Link Fence Fabric |

| ASTM A563 | (2015) Standard Specification for Carbon and Alloy Steel Nuts |

| ASTM A666 | (2015) Standard Specification for Annealed or Cold-Worked Austenitic Stainless Steel Sheet, Strip, Plate and Flat Bar |

| ASTM A702 | (2013) Standard Specification for Steel Fence Posts and Assemblies, Hot Wrought |

| ASTM A780/A780M | (2009; R 2015) Standard Practice for Repair of Damaged and Uncoated Areas of Hot-Dip Galvanized Coatings |

| ASTM A824 | (2011; R 2017) Standard Specification for Metallic-Coated Steel Marcelled Tension Wire for Use With Chain Link Fence |

| ASTM A1023/A1023M | (2019) Standard Specification for Stranded Carbon Steel Wire Ropes for General Purposes |

| ASTM B117 | (2016) Standard Practice for Operating Salt Spray (Fog) Apparatus |

| ASTM C94/C94M | (2018) Standard Specification for Ready-Mixed Concrete |

| ASTM F567 | (2014a) Standard Practice for Installation of Chain Link Fence |

| ASTM F626 | (2014) Standard Specification for Fence Fittings |

| ASTM F668 | (2017) Standard Specification for Poly(Vinyl Chloride) (PVC) and other Organic Polymer-Coated Steel Chain-Link Fence Fabric |

| ASTM F844 | (2007a; R 2013) Washers, Steel, Plain (Flat), Unhardened for General Use |

| ASTM F883 | (2013) Padlocks |

| ASTM F900 | (2011; R 2017) Standard Specification for Industrial and Commercial Swing Gates |

| ASTM F1043 | (2018) Standard Specification for Strength and Protective Coatings on Steel Industrial Fence Framework |

| ASTM F1083 | (2018) Standard Specification for Pipe, Steel, Hot-Dipped Zinc Coated (Galvanized) Welded, for Fence Structures |

| ASTM F1145 | (2017) Standard Specifications for Turnbuckles, Swaged, Welded, Forged |

| ASTM F1184 | (2016) Industrial and Commercial Horizontal Slide Gates |

| ASTM F1910 | (1998; R 2018) Standard Specification for Long Barbed Tape Obstacles |

| ASTM F1911 | (2005; R 2019) Standard Practice for Installation of Barbed Tape |

| ASTM F2408 | (2016) Standard Specification for Ornamental Fences Employing Galvanized Steel Tubular Pickets |

| ASTM F2589 | (2016) Standard Specification for Ornamental Fences Employing Steel Tubular Pickets |

| ASTM F2814 | (2009; R 2015) Standard Guide for Design and Construction of Ornamental Steel Picket Fence Systems for Security Purposes |

| ITALIAN NATIONAL ASSOCIATION FOR UNIFICATION OF STANDARDS (UNI) | |

| UNI EN 10223-6:2013 | Steel wire and wire products for fencing and netting - Part 6: Steel wire chain link fencing |

| UNI EN 10223-4:2013 | Steel wire and wire products for fencing and netting - Part 4: Steel wire welded mesh fencing |

| UNI EN 10223-7:2013 | Steel wire and wire products for fencing and netting - Part 7: Steel wire welded panels for fencing |

| UNI EN 10223-5:2013 | Steel wire and wire products for fencing and netting - Part 5: Steel wire woven hinged joint and knotted mesh fencing |

| UNI EN10223-2:2013 | Steel wire and wire products for fencing and netting - Part 2: Hexagonal steel wire netting for agricultural, insulation and fencing purposes |

| UNI EN 10223-3:2014 | Steel wire and wire products for fencing and netting - Part 3: Hexagonal steel wire mesh products for civil engineering purposes |

| UNI EN 10223-8:2014 | Steel wire and wire products for fencing and netting - Part 8: Welded mesh gabion products |

| UNI EN 10223-1:2013 | Steel wire and wire products for fencing and netting - Part 1: Zinc and zinc-alloy coated steel barbed wire |

1.2 SUBMITTALS

Government approval is required for submittals with a "G" designation; submittals not having a "G" designation are for information only. When used, a designation following the "G" designation identifies the office that will review the submittal for the Government. Submit the following in accordance with Section 01 33 00 SUBMITTAL PROCEDURES:

SD-02 Shop Drawings

Fence Installation Drawings; G

SD-03 Product Data

Fabric

Posts

Post Caps

Line Posts

Sleeves

Barbed Wire

Barbed Wire Supporting Arms

Barbed Tape

Latches

Hinges

Stops

Keepers

Rollers

Padlocks

Wire Ties

Slide Gates

Fence Fabric Reinforcement

SD-07 Certificates

Chain Link Fence

Fabric

Barbed Wire

Gate Hardware and Accessories

Concrete

SD-10 Operation and Maintenance Data

Operating and maintenance instructions; G

1.3 DELIVERY, STORAGE, AND HANDLING

Deliver materials to site in an undamaged condition. Store materials elevated off of the ground to protect against oxidation caused by ground contact.

PART 2 PRODUCTS

2.1 COMPONENTS

2.1.1 Chain Link Fence Fabric

2.1.1.1 General

Provide ASTM A392, Class 1, zinc-coated steel wire with minimum coating weight of 370 grams of zinc per square meter of coated surface. Fabricate fence fabric of 9 gauge wire woven in 25 mm mesh conforming to ASTM A116. Provide manufacturer's standard RAL 8002 in color for polyvinyl chloride coating for fabric and all other fence components.

2.1.2 Posts

2.1.2.1 Metal Posts for Chain Link Fence

Provide posts conforming to ASTM F1083, zinc-coated. Group IA, with external coating Type A steel pipe. Group IC steel pipe, zinc-coated with external coating Type A or Type B and Group II, roll-formed steel sections, meeting the strength and coating requirements of ASTM F1043 and ASTM A702. Provide sizes as shown on the drawings. Use line posts and terminal (corner, gate, and pull) posts of the same designation throughout the fence. Provide gate post for the gate type specified subject to the limitation specified in ASTM F900 and/or ASTM F1184.

2.1.2.2 Accessories

- a. Provide accessories conforming to ASTM F626. Coat ferrous accessories with zinc or aluminum coating.. Match color coating of fittings to color coating of the fabric.

- b. Provide truss rods (with turnbuckles or other means of adjustment)for each terminal post.

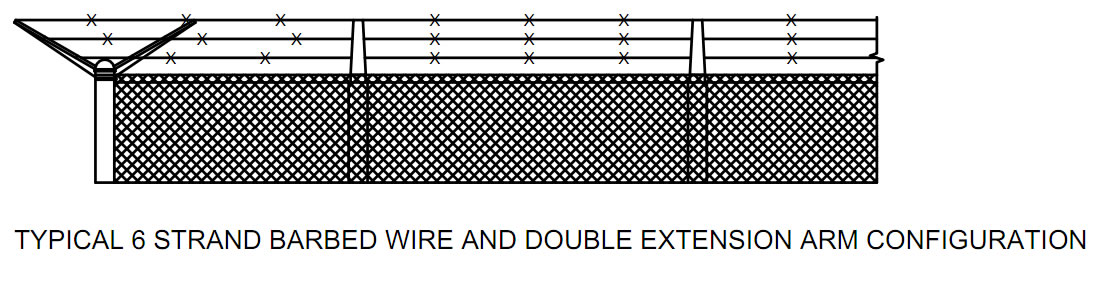

- c. Provide barbed wire supporting arms of the V 6 strand arm type and of the design required for the post furnished. Secure arms by bolting.

- d. Furnish post caps in accordance with manufacturer's standard accessories.

2.1.3 Chain Link Gates

2.1.3.1 Gate Assembly

Provide gate assembly conforming to ASTM F900 and/or ASTM F1184 of the type shown. Provide gate frames conforming to strength and coating requirements of ASTM F1083 for Group IA, steel pipe, with external coating Type A, nominal pipe size (NPS) 50. Provide gate frames conforming to strength and coating requirements of ASTM F1043, for Group IC, steel pipe with external coating Type A or Type B, nominal pipe size (NPS) 50.

2.1.3.2 Gate Leaves

For gate leaves, more than 2.44 m wide, provide either intermediate members and diagonal truss rods or tubular members as necessary to provide rigid construction, free from sag or twist. For gate leaves less than 2.44 m wide, provide truss rods or intermediate braces. Provide intermediate braces on all gate frames with an electro-mechanical lock. Attach fabric to the gate frame by method standard with the manufacturer. Welding is not an acceptable method for attaching fabric to gate frames.

2.1.3.3 Gate Hardware and Accessories

Submit manufacturer's catalog data. Furnish and install latches, hinges, stops, keepers, rollers, and other hardware items as required for the operation of the gate. All items are required to match the material characteristics of the fence system being installed. Arrange latches for padlocking so that the padlock will be accessible from both sides of the gate. Provide stops for holding the gates in the open position. For high security applications, extend each end member of gate frames sufficiently above the top member to carry three strands of barbed wire in horizontal alignment with barbed wire strands on the fence.

2.1.4 Padlocks

Provide padlocks conforming to ASTM F883, Type PO1, Option A, B, and G, Grade 6. Size 44 mm. Key all padlocks into master key system as specified in Section 08 71 00 DOOR HARDWARE.

2.2 MATERIALS

2.2.1 Wire

2.2.1.1 Wire Ties

Submit samples as specified. Provide wire ties constructed of the same material as the fencing fabric.

2.2.1.2 Barbed Wire

Provide barbed wire conforming to ASTM A121 zinc-coated, Type Z, Class 3, or aluminum-coated, Type A, with 12.5 gauge wire with 14 gauge, round, 4-point barbs spaced no more than 125 mm apart.

2.2.2 Barbed Tape

Provide reinforced barbed tape, for fence toppings fabricated from 430 series stainless steel with a hardness range of Rockwell (30N) 37-45 conforming to the requirements of ASTM A240/A240M. Provide stainless steel strip 0.6 mm thick by 25 mm wide before fabrication. Provide barbs that are a minimum of 30.5 mm in length, in groups of 4, spaced on 102 mm centers. Use stainless steel core wire with a 2.5 mm diameter and a minimum tensile strength of 9.68 MPa and conforming to ASTM A478. Use 1.3 mm stainless steel twistable wire ties for attaching the barbed tape to the barbed wire.

Ensure long barbed tape obstacles conform to ASTM F1910.

2.2.3 Concrete

ASTM C94/C94M, using 19 mm maximum size aggregate, and having minimum compressive strength of 21 MPa at 28 days. Use grout consisting of one part portland cement to three parts clean, well-graded sand and the minimum amount of water to produce a workable mix.

2.3 FENCE FABRIC REINFORCEMENT

Provide galvanized structural wire rope as indicated and in accordance with ASTM A1023/A1023M, 20mm nominal diameter of strand, 19 wire strand, regular lay, extra improved plow steel (EIPS), independent wire rope core (IWRC) and with a minimum breaking strength of 9,175 Newtons. Galvanize cable, Class A, in accordance with ASTM A1023/A1023M.

2.3.1 Wire Rope Accessories

All structural steel members used in cable anchoring system shall be hot-dipped galvanized. Clamps, U-bolts, and associated hardware shall be hot-dipped galvanized in accordance with ASTM A153/A153M.

2.3.2 Turnbuckles

Turnbuckles shall be 30mm x 300mm x 300mm Type I, Grade 1 galvanized, in accordance with ASTM F1145. 2.3.3 Rope Clamps Rope clamps shall be hot-dipped galvanized in accordance with ASTM A153/A153M.

2.3.4 Threaded Rods, U-Bolts, and Bolts

All threaded rods, U-bolts shall conform to ASTM A307 and installed with ASTM F844 and ASTM A563 nuts. The entire bolt assembly shall be galvanized.

PART 3 EXECUTION

3.1 PREPARATION

Perform complete installation conforming to ASTM F567.

3.1.1 Line and Grade

Install fence to the lines and grades indicated. Clear the area on either side of the fence line to the extent indicated. Space line posts equidistant at intervals not exceeding 3 m. Set terminal (corner, gate, and pull) posts whenever abrupt changes in vertical and horizontal alignment are encountered. Provide continuous fabric between terminal posts; however, ensure runs between terminal posts do not exceed 152.4 m. Repair any damage to galvanized surfaces, including welding, with paint containing zinc dust in accordance with ASTM A780/A780M.

3.1.2 Excavation

Excavate holes to depths indicated. Clear all post holes of loose material and spread waste material where directed. Eliminate ground surface irregularities along the fence line.

3.2 INSTALLATION

3.2.1 Installation Drawings

Submit complete Fence Installation Drawings for review and approval by the Contracting Officer prior to shipment. Submit drawing details that include, but are not limited to the following information: Fence Installation Drawings, Location of gate, corner, end, and pull posts, Gate Assembly, and Gate Hardware and Accessories. Install fence system per approved drawings.

3.2.2 Security Fencing

Install new security fencing, remove existing security fencing, and perform related work to provide continuous security for facility. Schedule and fully coordinate work with Contracting Officer.

3.2.3 Posts

3.2.3.1 Earth and Bedrock

- a. Set posts plumb and in alignment. Except where solid rock is encountered, set posts in concrete to the depth indicated on the drawings. Where solid rock is encountered with no overburden, set posts to a minimum depth of 457 mm in rock. Where solid rock is covered with an overburden of soil or loose rock, set posts to the minimum depth indicated on the drawing unless a penetration of 457 mm in solid rock is achieved before reaching the indicated depth, in which case terminate depth of penetration. Grout all portions of posts set in rock.

- b. Set portions of posts not set in rock in concrete from the rock to ground level. Set posts in holes not less than the diameter shown on the drawings. Make diameters of holes in solid rock at least 25 mm greater than the largest cross section of the post. Thoroughly consolidate concrete and grout around each post, free of voids and finished to form a dome. Allow concrete and grout to cure for 72 hours prior to attachment of any item to the posts. Group II line posts may be mechanically driven, for temporary fence construction only, if rock is not encountered. Set driven posts to a minimum depth of 914 mm and protect with drive caps when setting.

- c. Test fence post rigidity by applying a 222.4 newtons force on the post, perpendicular to the fabric, at 1.52 m above ground. Ensure post movement measured at the point where the force is applied is less than or equal to 19 mm from the relaxed position. Test every tenth post for rigidity. When a post fails this test, make further tests on the next four posts on either side of the failed post. Remove, replace, and retest all failed parts at the Contractor's expense.

3.2.3.2 Concrete Slabs and Walls

When installed in concrete slabs or walls, set posts in zinc-coated sleeves, to a minimum depth of 300 mm. Fill sleeve joint with lead, nonshrink grout, or other approved material. Set posts for support of removable fence sections in sleeves that provide a tight sliding joint and hold posts aligned and plumb without use of lead or setting material.

3.2.4 Supporting Arms

Install barbed wire supporting arms and barbed wire as indicated on the drawings and as recommended by the manufacturer. Anchor supporting arms with 9.5 mm diameter plain pin rivets or, at the Contractor's option, with studs driven by low-velocity explosive-actuated tools for steel, wrought iron, ductile iron, or malleable iron. Do not use explosive-actuated tool to drive studs into gray iron or other material that can be fractured. Use a minimum of two studs per support arm. Pull barbed wire taut and attach to the arms with clips or other means that will prevent easy removal.

3.2.5 Barbed Tape Installation

Install stainless steel reinforced barbed tape per ASTM F1911 and as detailed on the drawings. Stretch out barbed tape to its manufacturer's recommended length, set on top of the barbed wire and "V" shaped support arms, then secure it to the barbed wire. Secure the barbed tape to the barbed wire at the two points and at every spiral turn of both coils as shown on the drawings.

3.2.6 Gate Installation

a. Install gates at the locations shown. Install latches, stops, and keepers as required. Install Slide gates as recommended by the manufacturer.

b. Attach padlocks to gates or gate posts with chains. Weld or otherwise secure hinge pins, and hardware assembly to prevent removal.

c. Submit 6 copies of operating and maintenance instructions. Outline the step-by-step procedures required for system startup, operation, and shutdown. Include the manufacturer's name, model number, service manual, parts list, and brief description of all equipment and their basic operating features. Include in the maintenance instructions routine maintenance procedures, possible breakdowns and repairs, and troubleshooting guide. Also include the general gate layout, equipment layout and simplified wiring and control diagrams of the system as installed.

3.2.7 Grounding

a. Ground fencing as specified.

b. Ground fences on each side of all gates, at each corner, at the closest approach to each building located within 15 m of the fence, and where the fence alignment changes more than 15 degrees. Ensure grounding locations are located no more than 198 m apart. Bond each gate panel with a flexible bond strap to its gate post. Ground fences crossed by powerlines of 600 volts or more at or near the point of crossing and at distances not exceeding 45 m on each side of crossing.

c. Provide ground conductor consisting of 3.3 mm solid copper wire. Use grounding electrodes that measures 19 mm by 3.05 m long and are a copper-clad steel rod. Drive electrodes into the earth so that the top of the electrode is at least 152 mm below the grade. Where driving is impracticable, bury electrodes a minimum of 305 mm deep and radially from the fence. Install the top of the electrode to be less than 610 mm or more than 2.4 m from the fence. Clamp ground conductorto the fence and electrodes with bronze grounding clamps to create electrical continuity between fence posts, fence fabric, and ground rods. Measure total resistance of the fence to ground and ensure it is not greater than 25 ohms.

3.2.8 Cable Reinforcement Installation

Comply with the contract drawings. Install 2 strands of 1.9 cm steel aircraft cables mounted to the chain link fence posts utilizing u-bolts and nuts. Peen the ends of the U-bolts to prevent removal. Tighten cables with galvanized steel turnbuckles with swaged fittings to the point there is no visible sag. Install .3 m x 1.3 m x 0.66 m concrete deadman anchors which are a minimum of 1.3 m underground and installed in undisturbed surrounding soils. Space dead man anchors no more than 61 m apart and on each side of gate openings. Connect steel aircraft cables to dead man anchors using swaged end fittings and turnbuckles attached to 3.2 cm galvanized threaded rod which is embedded into concrete anchor and held in place with two 10 cm x 10 cm x 0.66 cm thick steel plates welded to the threaded rod. Place deadman anchors within 3 m of last post and on each side of gate openings.

Doors for High Security Gates:

Major components: Door, hinges, locks and latches, exit devices, electrified hardware, keys, bolts.

Locks and latches: ANSI/BHMA A156.13 Series 1000 operational grade 1, security grade 2.

Hinges: ANSI/BHMA A1

Electrified door hardware components with ESS Electronic Security System standard for security doors and frames.

High security chain link sliding gate for naval facility fencing system

High security fence gates for area entry control:

Designed with security fence gates, reinforced by cable wire:

1,Fence post adjacent to gate end post.

2,Turn back and clamp fence reinforcing.

3, Extend cable beyond overhang and connect to fence reinforcing using a lock bar and plate.

4, Top rail provide gate frame in accordance to manufactures recommendation.

5, Bottom rail provide gate frame in accordance to manufactures recommendation

Posts: 100mm square post,

50mm square post

Barbed wire strands: (3) strands of barbed wire

Barbed wire type:

2 strand line wire w/ 4 pt barbs

Wire rope clamp fixing:

Wire rope clamp

19mm cable reinforcing provide twist-off metal ties to secure cable to fabric & u-bolts to secure to uprights

Wire rope clamps provide fence post adjacent to gate end post.

Turn back and clamp fence reinforcing.

Extend cable wire beyond overhang and connect to fence reinforcing using a lock bar and plate.

Ensure cable installed to allow drop bar to pass through plates and connect all 4 cables

Supply u-bolt to fix gate cable to frame upright

Supply Extra heavy duty wire rope thimble

Provide two locking bar tab plates on the terminating gate post

Warning tape 200mm

Copper tracer wire (3mm DIA)

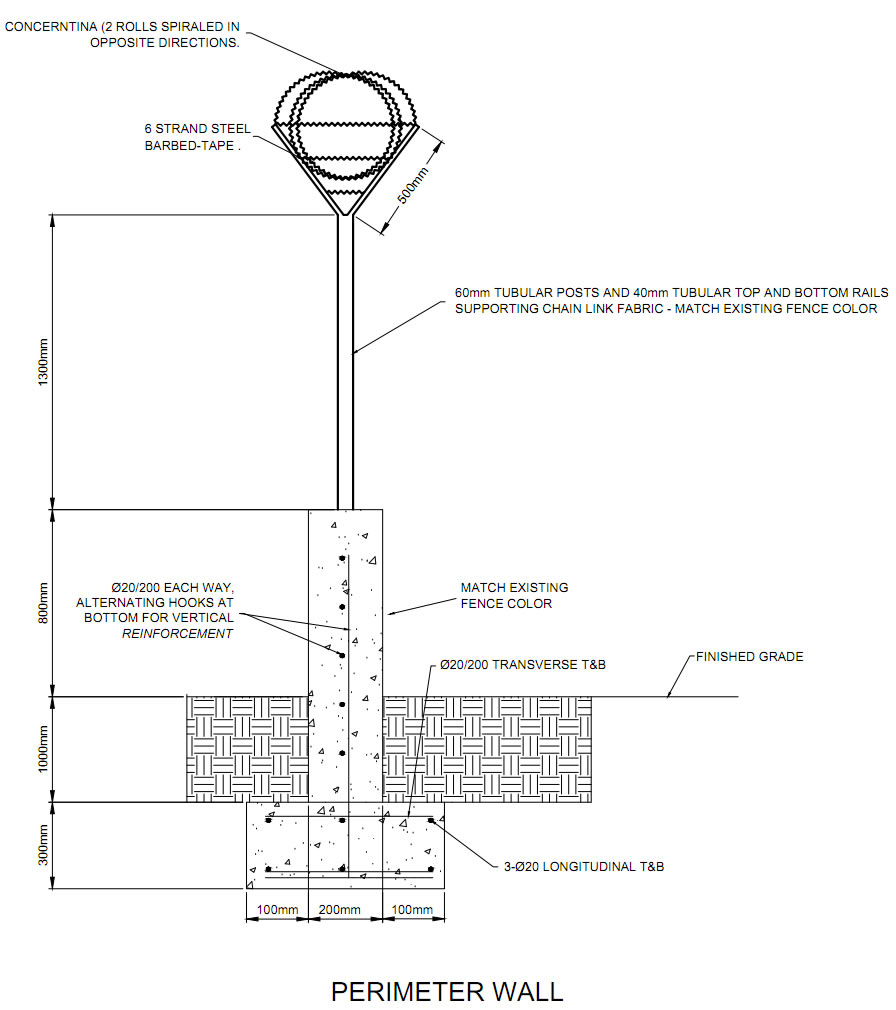

6 STRAND STEEL BARBED-TAPE .

Steel barbed-tape concertina 2 rolls spiraled in opposite directions.

Supporting posts with arms: 60mm TUBULAR POSTS with extension arms for barbed tapes

40mm Tubular top and bottom rails supporting chain link fabric.

Customized Services

Contact us with your high security fencing needs, for entry control, for facilities protection, we will offer a competitive pricing with detail information:

- Description of the High Security Fence and Gates

- Pricing details, including any package options available

- Any customization options and associated costs, if applicable

- Terms and conditions, including payment terms

-

Relevant portfolio showcasing our High Security Fence and Gates